For the professional truck driver, safety isn't just a priority; it's the foundation of a long and successful career. The road presents countless variables, from unpredictable weather and traffic to the immense responsibility of handling an 80,000-pound vehicle. Mastering a core set of safety practices transforms a good driver into a great one, capable of anticipating hazards and navigating challenges with confidence. This guide provides an in-depth roundup of critical truck driving safety tips, moving beyond the obvious to offer actionable strategies that protect you, your cargo, and everyone else on the highway.

Inside this guide, we will break down essential protocols covering every aspect of the job. You'll find detailed advice on everything from conducting meticulous pre-trip inspections and managing your hours of service to mastering defensive driving techniques for hazard recognition. We will also cover specific procedures for securement checks, adapting to adverse weather, and safely executing difficult maneuvers like backing. Whether you're a new graduate or a seasoned veteran looking to reinforce best practices, these principles are designed to keep you safe, compliant, and profitable on every haul. Let's dive into the tips that will help you steer clear of danger.

1. Pre-Trip Vehicle Inspection

A foundational habit for every safe and professional driver is the pre-trip vehicle inspection. This isn't just about ticking boxes on a form; it's a systematic, hands-on check of your truck and trailer’s critical systems before you ever turn the key. Mandated by the Federal Motor Carrier Safety Administration (FMCSA), this routine is your first line of defense against mechanical failures on the road. By dedicating time to this process, you can identify and address potential safety hazards before they escalate into dangerous situations, protecting yourself, your cargo, and others.

Major carriers have quantified the immense value of this practice. FedEx, for example, credits diligent pre-trip inspections with preventing over 12,000 potential breakdowns in a single year. This proactive approach not only enhances safety but also saves millions in repair costs through early problem detection.

Implementing Your Inspection

To make your inspection effective, consistency is key. Don't rely on memory alone; use a standardized checklist every time to cover all essential components, from brakes and tires to lights and cargo securement.

- Create the Right Environment: Always perform your inspection in good lighting. If you're starting before dawn, use a powerful flashlight to see clearly.

- Take Your Time: Rushing leads to mistakes. A thorough inspection takes a minimum of 15 to 30 minutes. Use all the time you need.

- Document Everything: Immediately note any defects, no matter how small, on your Driver Vehicle Inspection Report (DVIR).

- When in Doubt, Ask: If you find something questionable, don't risk it. Have a qualified mechanic perform a detailed inspection.

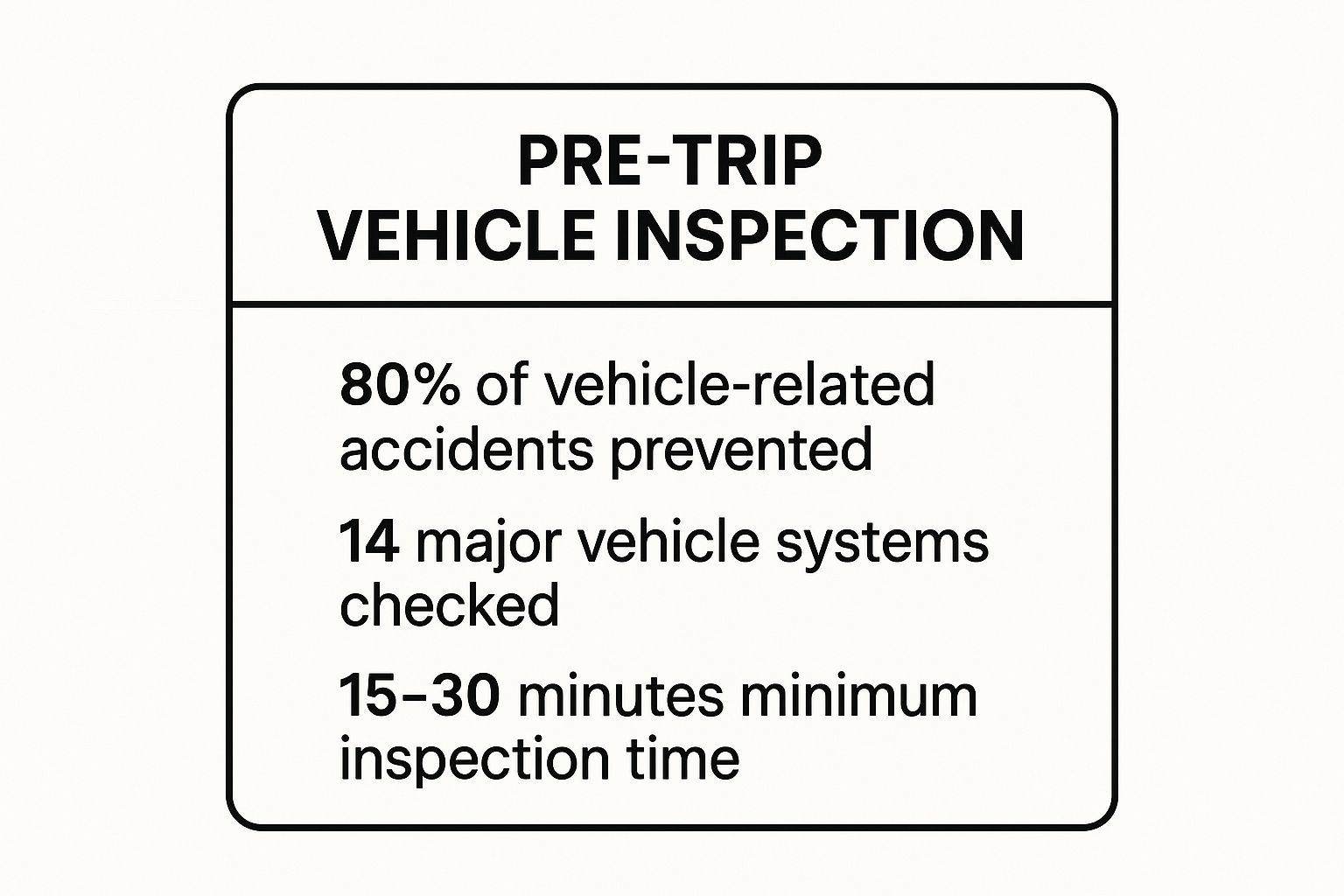

The following graphic summarizes the core impact and commitment of a proper pre-trip inspection.

These numbers highlight how a small-time investment checking key vehicle systems can yield a massive return in accident prevention. Integrating this non-negotiable step into your daily routine is one of the most impactful truck driving safety tips you can adopt.

2. Proper Following Distance (3-Second Rule Plus)

Mastering space management is a non-negotiable skill for professional drivers, and it starts with maintaining a proper following distance. While passenger cars often use a three-second rule, a fully loaded commercial truck requires significantly more space and time to stop safely. The "3-Second Rule Plus" is an advanced technique, advocated by organizations like the National Safety Council, that adapts this principle for heavy vehicles. It requires maintaining a minimum of 4 to 6 seconds of space behind the vehicle ahead, providing a crucial buffer for reaction time, brake lag, and the sheer physics of halting up to 80,000 pounds.

The impact of this safety buffer is well-documented. Major carriers like Swift Transportation have seen remarkable results, reducing rear-end accidents by as much as 60% after implementing enhanced following distance training. Similarly, companies such as Werner Enterprises and Prime Inc. integrate telematics data on following distance directly into driver safety scores, reinforcing its importance as a core professional habit.

Implementing Your Space Cushion

Making this technique an automatic part of your driving requires conscious practice. Use a fixed point of reference to measure your distance and adjust based on road conditions.

- Count the Seconds: When the vehicle ahead passes a fixed object like a sign or overpass, start counting "one-thousand-one, one-thousand-two…" You should reach at least "one-thousand-four" before your truck passes the same object.

- Add Time for Conditions: Increase your following distance to 6-8 seconds or more during adverse weather like rain or snow, at night, or in heavy traffic.

- Anticipate and Adjust: Look far ahead to anticipate changes in traffic flow. This allows you to ease off the accelerator to maintain space rather than relying on heavy braking.

- Stay Calm When Cut Off: If a car merges into your safety cushion, don't react with sudden braking. Simply lift off the throttle and gradually re-establish your proper following distance.

This proactive approach to space management is one of the most effective truck driving safety tips for preventing collisions and demonstrating professionalism on the road.

3. Hours of Service Compliance and Fatigue Management

Staying alert behind the wheel is a non-negotiable aspect of professional driving, making strict adherence to Hours of Service (HOS) regulations a cornerstone of truck driving safety tips. These federal rules are not just bureaucratic hurdles; they are life-saving limits on driving time designed to combat the severe risks of driver fatigue. By mandating rest breaks, daily driving limits, and weekly rest periods, HOS rules provide a framework for ensuring drivers are sufficiently rested and fully capable of safely operating their vehicles.

The industry-wide impact of enforcing these rules is clear. Since the 2017 mandate for Electronic Logging Devices (ELDs), HOS compliance rates have soared to over 95%, directly contributing to safer roads. Major fleets like Walmart's private fleet have demonstrated the power of combining compliance with proactive training, reducing fatigue-related incidents by a remarkable 40%. This proves that managing fatigue is as critical as any mechanical check.

Implementing Your Fatigue Management Strategy

Effective fatigue management goes beyond simply following the clock. It requires a personal commitment to recognizing your body's limits and prioritizing rest to maintain peak performance.

- Plan Around HOS: Before you start a trip, map out your route with mandatory breaks and rest periods in mind. Proactive planning prevents the dangerous temptation to push your limits.

- Take Proactive Breaks: Don't wait until you feel exhausted. Step out of the cab for short breaks to stretch and refresh, even if you have driving time left.

- Prioritize Sleep Quality: Aim for a consistent sleep schedule, even on the road. Make your sleeper berth as dark, quiet, and comfortable as possible.

- Recognize Early Warning Signs: Be mindful of signs like frequent yawning, heavy eyelids, or drifting from your lane. These are clear signals that it's time to pull over and rest immediately.

By integrating these personal strategies with regulatory compliance, you transform HOS from a requirement into a powerful tool for personal safety. A thorough understanding of these rules is a fundamental part of modern truck driver training.

4. Defensive Driving and Hazard Recognition

Defensive driving is a proactive mindset that empowers you to control your environment by anticipating and reacting to potential dangers before they materialize. This goes beyond simply following traffic laws; it's about actively identifying hazards, maintaining situational awareness, and creating a buffer zone to account for unpredictable actions from other drivers or sudden changes in road conditions. Mastering this skill is a cornerstone of professional truck driving safety tips, transforming you from a passive road user into an active guardian of your safety.

The impact of this approach is well-documented. Leading carriers like UPS build their entire safety culture around defensive driving systems, while FedEx Ground has attributed a 35% reduction in preventable accidents to comprehensive hazard perception training. These programs underscore a vital truth: the best way to handle a dangerous situation is to avoid it altogether.

Implementing Defensive Driving

True defensive driving is an active, continuous process, not a passive one. It requires constant engagement and a commitment to seeing the bigger picture on the road ahead. You can find comprehensive information on these techniques to prepare for your general knowledge test.

- Scan 12-15 Seconds Ahead: Constantly look far down the road to see traffic patterns, potential slowdowns, and road hazards well before you reach them. This gives you ample time to react smoothly.

- Check Mirrors Frequently: A quick glance at your mirrors every 5-8 seconds keeps you aware of what’s happening beside and behind your rig.

- Maintain Your Escape Routes: Always leave yourself an "out." Avoid getting boxed in by other vehicles, ensuring you have space to move left, right, or slow down if a hazard appears.

- Never Assume: Do not assume another driver sees you, will yield the right-of-way, or will follow traffic signals. Be prepared for others to make mistakes.

By integrating these practices into every mile you drive, you build a powerful, proactive defense against the most common causes of collisions, making you a safer and more professional driver.

5. Proper Load Securement and Weight Distribution

One of the most critical truck driving safety tips involves mastering proper load securement and weight distribution. This goes far beyond simply tying down cargo; it's a science of maintaining vehicle stability, preventing dangerous load shifts, and ensuring full compliance with Department of Transportation regulations. An improperly secured or poorly distributed load can drastically alter your truck's center of gravity, leading to rollovers, lost cargo, and catastrophic accidents. This is why it's a non-negotiable skill for any professional driver.

Top-tier carriers emphasize this skill with dedicated training and technology. For instance, Roehl Transport successfully reduced its cargo damage claims by 50% after implementing an enhanced securement training program. Similarly, Stevens Transport utilizes advanced load securement simulators to provide drivers with hands-on education in a safe, controlled environment, proving that a focus on this area yields massive safety dividends.

Implementing Your Securement Strategy

Effective load securement is an active, ongoing process, not a one-time task at the start of your trip. Building a routine around checking your load is essential for preventing issues down the road.

- Inspect Equipment First: Before every use, thoroughly check all chains, straps, binders, and winches for signs of wear, cracks, or damage. Never use compromised equipment.

- Follow the 150-Mile Rule: Check your load securement within the first 50 miles of your trip and then again every 150 miles or every three hours, whichever comes first. Also, check after any hard braking or significant road event.

- Exceed the Minimum: When practical, use more tie-downs than the minimum regulatory requirement. This provides an extra margin of safety against unexpected forces.

- Understand Your Limits: Know the Working Load Limit (WLL) of all your securement devices and ensure their combined WLL meets or exceeds the weight of the cargo being secured.

- Account for Settling: Cargo can settle, compress, or shift during transit, causing tie-downs to loosen. Be mindful of this and re-tighten as needed during your stops.

A secure load is a stable load, and understanding the dynamics of different cargo types is key to road safety. Properly distributing weight and applying the right securement techniques for combination vehicles are fundamental skills. This disciplined approach is a cornerstone of professional driving and directly prevents countless incidents.

6. Weather Adaptation and Adverse Condition Driving

Operating a commercial vehicle safely means being a master of adaptation, especially when the weather turns hostile. Adverse condition driving involves specialized techniques and critical decision-making for navigating rain, snow, ice, fog, and high winds. This goes beyond simply slowing down; it’s a comprehensive approach to managing risk when visibility is low, traction is compromised, and external forces like wind can affect your vehicle’s stability. A professional driver knows that sometimes the safest decision is not to drive at all.

This commitment to safety is a core principle for leading carriers. Prime Inc., for example, supports drivers who make the call to shut down for weather safety by offering detention pay, reinforcing that safety is more valuable than mileage. Similarly, Schneider National equips its drivers with real-time weather routing technology, helping them proactively avoid dangerous systems instead of reacting to them.

Implementing Your Adverse Weather Strategy

To implement this crucial set of truck driving safety tips, you must shift your mindset from "getting there on time" to "getting there safely." This means prioritizing caution over the schedule when conditions deteriorate.

- Adjust Speed and Following Distance: A standard rule is to reduce your speed by one-third on wet roads and by at least half on snow-covered roads. Double your following distance to a minimum of 8-10 seconds to allow for increased stopping time.

- Test Your Brakes: When conditions change, gently test your brakes in a safe area to understand how the road surface is affecting your traction and stopping power.

- Know When to Stop: If visibility drops significantly, such as below a quarter-mile in heavy fog or a whiteout, it is time to find a safe place to pull over and wait for conditions to improve. Do not stop on the shoulder unless it's a true emergency.

- Carry Emergency Supplies: Always be prepared for an extended stop. Keep a kit with extra food, water, blankets, warm clothing, and a fully charged phone or power bank.

Adopting these defensive driving habits in adverse weather is a non-negotiable part of being a professional. By respecting the power of Mother Nature and adjusting your driving accordingly, you protect your own life, the public, and your cargo.

7. Backing and Maneuvering Safety Protocols

Backing incidents are among the most common, costly, and preventable accidents in the trucking industry. Implementing systematic backing and maneuvering safety protocols is a non-negotiable truck driving safety tip for every professional. This approach transforms a high-risk activity into a controlled, predictable process by relying on established principles like G.O.A.L. (Get Out And Look) rather than guesswork. It's a structured method for navigating tight docks, crowded yards, and other confined spaces with confidence and precision.

Companies that enforce these protocols see dramatic safety improvements. Walmart's private fleet, for example, slashed backing accidents by an impressive 80% after implementing systematic procedures. Similarly, UPS reports saving over $1 million annually thanks to its mandatory G.O.A.L. policies, proving that a few moments of caution prevent significant financial and operational losses.

Implementing Your Maneuvering Plan

A successful backing maneuver starts before you even shift into reverse. It requires a clear plan and a commitment to situational awareness. Treat every backing situation as a unique challenge that demands your full attention.

- Set Up for Success: Whenever possible, position your truck to back from the driver's side (a sight-side back). This provides the best visibility and reduces dangerous blind spots.

- Use a Spotter Correctly: If a spotter is available, agree on clear, simple hand signals before the maneuver begins. The driver is always in command, but a trusted spotter is an invaluable asset.

- Control Your Speed: Back up slowly, no faster than a walking pace (idle speed). This gives you ample time to react to any unforeseen obstacles or misjudgments.

- Embrace the G.O.A.L. Principle: Get Out And Look. Stop the truck, get out, and walk a full circle to check your clearances. Never feel rushed; if you are even slightly unsure, stop and G.O.A.L. again.

The following video demonstrates the G.O.A.L. principle and other critical backing techniques in a real-world setting.

By making these protocols an unbreakable habit, you can virtually eliminate the risk of backing accidents. This commitment not only protects property but also reinforces your status as a safe, professional driver.

8. Blind Spot Awareness and Mirror Management

Mastering the significant blind spots around a commercial vehicle is a non-negotiable skill for every professional driver. These areas, often called "No-Zones," are large fields of view where smaller vehicles disappear completely. They can extend over 20 feet in front of the cab, 30 feet behind the trailer, and across entire lanes on both sides of the truck. Proper mirror management and constant situational awareness are your primary tools to mitigate the immense risk these blind spots create.

Leading transportation companies have proven that focusing on this critical skill dramatically reduces collisions. For instance, J.B. Hunt credits its enhanced blind spot training programs with a 45% reduction in side-impact accidents. Similarly, carriers like Knight Transportation proactively install additional convex mirrors to minimize No-Zones, making this one of the most impactful truck driving safety tips for preventing lane-change incidents.

Implementing Your Awareness Strategy

Effective blind spot management is an active, continuous process, not a passive one. It requires integrating systematic checks into your driving rhythm to maintain a 360-degree mental map of the traffic around you.

- Adjust Before You Drive: Before starting any trip, ensure all your mirrors are perfectly adjusted for your specific seating position. Proper alignment is your first and best defense.

- Scan Systematically: Constantly move your eyes in a pattern: left mirror, windshield, right mirror, and check your gauges. This rhythm keeps you updated on the entire traffic environment.

- Signal with Intention: Signal your intention to change lanes well in advance. This gives other drivers time to react and may encourage them to move out of your blind spot.

- Confirm and Re-Confirm: Before making any lateral move, check your mirrors multiple times. A vehicle that wasn't there two seconds ago might be there now. If you cannot see a full vehicle in your mirror, assume the space is occupied.

This visual representation underscores the massive areas you must actively monitor. By making diligent mirror checks and respecting the No-Zone a core part of your driving habits, you directly prevent some of the most common and dangerous types of highway accidents.

9. Master Mirror and Blind Spot Management

Even with the best mirrors, a commercial truck has significant blind spots, commonly known as "No-Zones." Mastering mirror usage and blind spot awareness is a critical truck driving safety tip that prevents sideswipes, lane-change collisions, and dangerous interactions with smaller vehicles. These zones are located directly in front of the cab, directly behind the trailer, and along both sides of the truck, extending out at an angle. Failing to account for these areas is a leading cause of preventable accidents.

The "If you can't see my mirrors, I can't see you" rule is a good start, but professional drivers must take a more proactive approach. The National Safety Council emphasizes that a driver’s ability to constantly scan and anticipate movements of other vehicles is paramount. Technology like blind-spot monitoring systems adds a layer of safety, but it never replaces the fundamental skill of manual, visual scanning. A driver who can expertly manage their visual field significantly reduces their risk profile on the road.

Implementing Your Blind Spot Strategy

Effective blind spot management is an active, continuous process, not a passive one. It requires integrating consistent habits into every moment you're behind the wheel.

- Adjust Mirrors Correctly: Before every trip, ensure your flat and convex mirrors are positioned to minimize blind spots and provide a clear, panoramic view of adjacent lanes.

- Scan Constantly: Make it a habit to scan your mirrors every 5-8 seconds. This keeps you aware of the ever-changing traffic patterns around your vehicle.

- Look Before You Move: Before any lane change, turn, or merge, perform a thorough check of all mirrors and lean forward to "look around" the A-pillar to clear that common blind spot.

- Assume You're Unseen: Operate under the assumption that smaller vehicles in your No-Zones cannot see you. This mindset encourages more cautious and defensive driving maneuvers.

By making diligent mirror checks and blind spot management an ingrained habit, you create a buffer of safety that protects you and everyone sharing the road. This is one of the most impactful truck driving safety tips for preventing common and often severe collisions.

Truck Driving Safety Tips Comparison Table

| Safety Practice | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Pre-Trip Vehicle Inspection | Moderate to High: Requires technical knowledge and 15-30 minutes per inspection | Driver time, inspection tools, paperwork | Prevents 80% of vehicle-related accidents; reduces breakdowns | Every trip start; DOT mandated for commercial vehicles | Prevents costly failures; ensures legal compliance |

| Proper Following Distance (3-Second Rule Plus) | Low: Simple timing method but requires constant adjustment | Driver attention and time buffer | Reduces rear-end collisions by up to 70% | Highway and congested traffic conditions | Improves safety and fuel efficiency; reduces stress |

| Hours of Service Compliance and Fatigue Management | Moderate: Requires adherence to complex regulations and scheduling | ELD devices, planning tools | Reduces fatigue-related accidents by 25-30% | Long haul, overnight shifts, regulated driving hours | Ensures rest; legal compliance; standardizes industry safety |

| Defensive Driving and Hazard Recognition | High: Continuous scanning and mental effort required | Training programs and driver focus | Prevents up to 90% of avoidable accidents | All driving conditions; high-risk environments | High accident prevention; improves driver confidence |

| Proper Load Securement and Weight Distribution | Moderate to High: Requires cargo knowledge and securement time | Securement equipment, training | Prevents load shift accidents and DOT violations | Loading/unloading; hauling diverse cargo | Maintains vehicle stability; avoids fines and accidents |

| Weather Adaptation and Adverse Condition Driving | Moderate: Requires specialized knowledge and flexible driving | Weather monitoring tools, extra equipment | Reduces weather-related accidents by up to 60% | Driving in rain, snow, ice, fog, high winds | Enhances safety under adverse conditions; protects cargo |

| Backing and Maneuvering Safety Protocols | Moderate: Requires systematic procedures and sometimes spotters | Spotters, mirrors, camera systems | Eliminates up to 95% of backing accidents | Tight spaces, yards, loading docks | Prevents collisions; reduces costly damage |

| Blind Spot Awareness and Mirror Management | Low to Moderate: Requires proper mirror setup and frequent scanning | Mirrors, blind spot technology | Reduces lane-change and merging accidents significantly | Lane changes, merging, urban driving | Enhances situational awareness; prevents side-impact crashes |

Making Safety a Lifelong Habit on the Road

Navigating the nation's highways in a commercial vehicle is a responsibility of the highest order. The extensive list of truck driving safety tips covered in this guide, from meticulous pre-trip inspections to mastering blind spots and adapting to severe weather, are more than just items on a checklist. They are the fundamental building blocks of a professional driver's mindset, where vigilance, discipline, and proactive awareness are second nature. The journey to becoming a truly safe and effective driver is not a final destination; it is a continuous process of learning, adapting, and recommitting to these core principles with every mile traveled.

True professionalism on the road is defined by consistency. It’s about performing a thorough vehicle inspection even when you're behind schedule, maintaining a safe following distance when traffic is heavy, and choosing to pull over when fatigue sets in, regardless of pressure to push forward. These individual decisions, repeated daily, create a powerful culture of safety that protects you, your cargo, and every other person sharing the road. Complacency is the greatest threat to an experienced driver, while impatience can be the downfall of a new one. By actively integrating these practices into your routine, you transform them from tasks into unwavering habits.

Key Takeaways for a Safer Career

To truly embed these concepts, focus on these critical action points:

- Embrace the Routine: Make the pre-trip and post-trip inspections non-negotiable parts of your day. A small issue caught in the yard is infinitely better than a major failure on the interstate.

- Master Your Space: Constantly manage the space cushion around your vehicle. This includes your following distance, your blind spots, and your overhead clearance. This space is your most valuable safety tool, giving you the time and room to react to unexpected hazards.

- Prioritize Rest Over Miles: Acknowledge the real dangers of fatigue. Adhering to Hours of Service regulations is the minimum standard; listen to your body and know when you need to rest. A well-rested driver is an alert and safe driver.

The Lasting Impact of Your Commitment

By dedicating yourself to these truck driving safety tips, you do more than just comply with regulations. You elevate your career, enhance your reputation as a professional, and contribute to a safer transportation industry for everyone. The skills you master in backing, hazard recognition, and defensive driving directly translate into a long, successful, and incident-free career. This commitment is the ultimate investment in your own well-being and your future on the open road, solidifying your role as a true guardian of the highway.

Ready to build your career on a foundation of safety and skill? Patriot CDL provides comprehensive, hands-on training that ingrains these essential safety habits from day one. Learn from experienced instructors and start your journey to becoming a confident, professional driver.